Polylactic acid (PLA) is a fully compostable bioplastic made from renewable plant-based materials, such as corn, cassava, or sugarcane. PLA is an eco-friendly alternative to traditional plastics such as PET and polystyrene, commonly used for cups, containers, and packaging films. It reduces reliance on fossil fuels while supporting a circular economy.

Quick PLA Facts:

- Source: Bio-based polymer derived from fermented plant sugars (e.g., corn, sugarcane, or cassava).

- Disposal: Compostable only in specific Industrial Composting Facilities. It cannot be reliably home composted or mixed with traditional plastics recycling.

- Performance: Offers high clarity and a glossy finish but is best for cold items due to low heat tolerance. Requires crystallization (CPLA) for hot food/liquids.

- Primary Use: Single-use food service items for cold applications such as clear cups, salad containers, lids, disposable cutlery, and flexible packaging films.

What is PLA (Polylactic Acid)?

Polylactic acid (PLA) is a type of bioplastic made by fermenting plant sugars into lactic acid, which is then polymerized into a plastic-like material. Unlike conventional plastics made from petroleum, PLA is derived from renewable resources, making it a more sustainable food packaging option.

Key benefits of PLA packaging:

- Sustainable: Uses plant-based materials that regrow every year, reducing dependence on fossil fuels.

- Biodegradable: Designed to fully compost in certified facilities, closing the loop on single-use packaging.

- Non-toxic: Free from harmful chemicals like BPA or phthalates.

- High performance: Strong, rigid, and resistant to grease and moisture, making it ideal for foodservice needs.

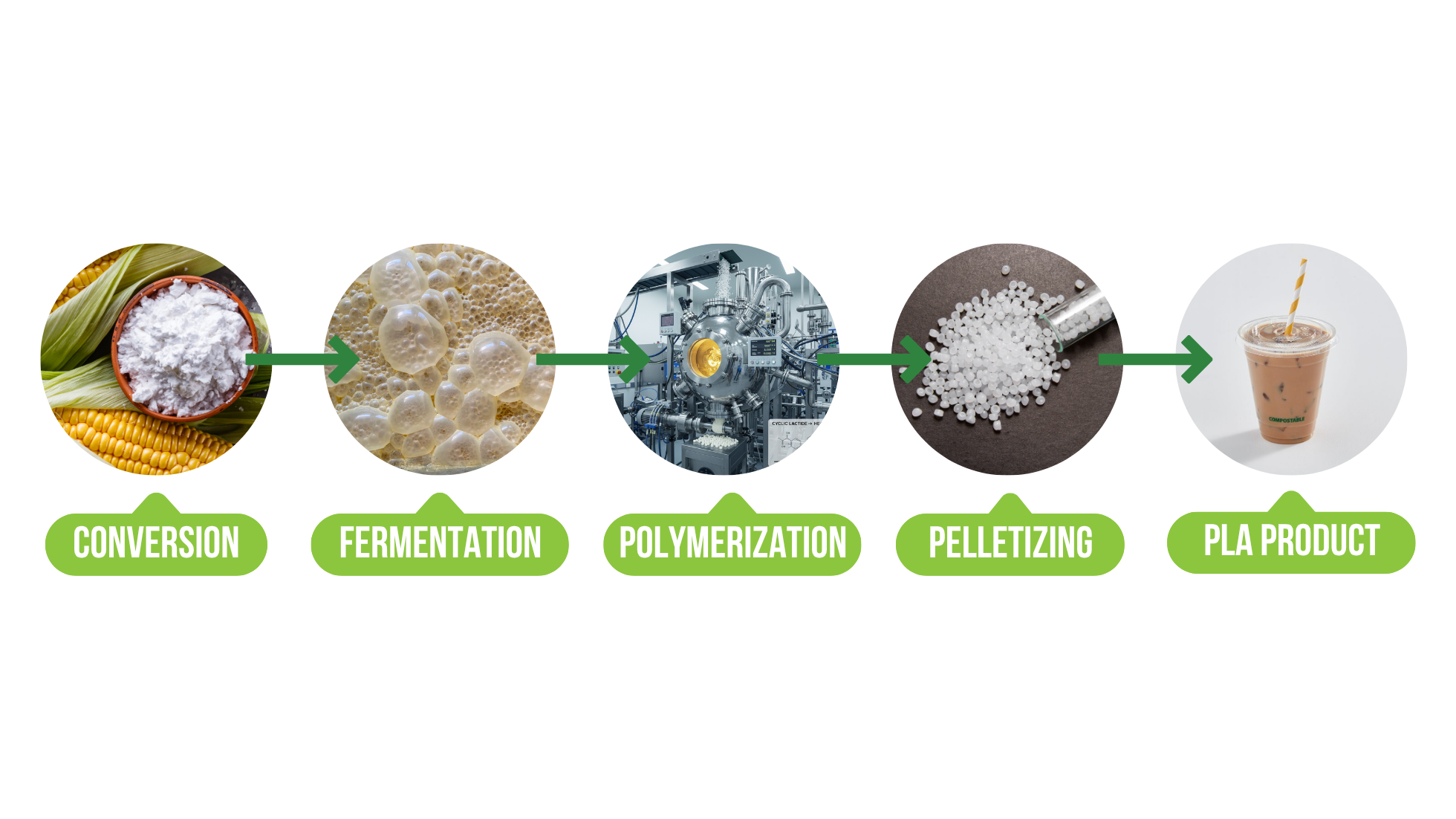

How is PLA (Polylactic Acid) Packaging Made?

PLA (polylactic acid) is made by transforming renewable plant materials such as corn, sugarcane, or cassava into a durable, food-safe bioplastic. The process combines natural fermentation with modern polymer science to turn simple sugars into a versatile packaging material.

- Step #1 Starch Conversion: The process begins with crops rich in natural starch. The starch is extracted and broken down with heat and enzymes to create simple plant-based sugars, which form the base for producing lactic acid.

- Step #2 Fermentation: The plant sugars are then placed in controlled conditions with specific microorganisms that feed on the sugars and turn them into lactic acid. This natural fermentation process gives PLA its name, polylactic acid, and is the first major step in transforming plants into a usable bioplastic.

- Step #3 Polymerization: The lactic acid is purified and processed into long molecular chains through polymerization. These chains give PLA its structure, durability, and flexibility, making it suitable for packaging and other practical uses.

- Step #4 Pelletizing: Once the polymerization process is complete, the PLA is cooled, dried, and cut into small plastic-like pellets. These pellets can be melted and molded into a wide range of products, from food containers and clear cups to coating layers for paper-based packaging.

Uses of PLA

PLA has quickly become one of the most widely used bioplastics in sustainable packaging and manufacturing. Its plant-based origin and ability to mimic the look and performance of conventional plastics make it a go-to choice for eco-conscious businesses across industries.

Here are some of the most common uses of PLA today:

- Food Packaging: Clear cups, clamshells, deli containers, and salad boxes that highlight freshness while keeping food secure.

- Liners and Coating: PLA films are used inside compostable paper cups and containers to provide leak resistance without petroleum-based plastic.

- Cutlery and Tableware: Sturdy enough for everyday use, yet compostable under the right conditions.

- 3D Printing: PLA filaments are among the most popular materials for 3D printing

PLA vs Plastic: Why PLA is Better for the Environment

Traditional plastics like PET (polyethylene terephthalate) are made from fossil fuels, taking centuries to decompose and releasing harmful microplastics into the environment. PLA, on the other hand, is a bioplastic derived from renewable crops like corn, sugarcane, or cassava. It looks and performs similarly to conventional plastic but leaves a much lighter footprint.

Here’s how they compare:

- Source: PLA comes from plants that can be replanted and renewed. PET relies on petroleum, a finite resource.

- Carbon Impact: Producing PLA can generate up to 70% fewer greenhouse gas emissions compared to PET plastic.

- End of Life: PLA is industrially compostable, breaking down into natural components under the right conditions. PET, in contrast, can persist in landfills for 400+ years.

- Toxicity: PLA doesn’t leach harmful chemicals when exposed to heat or food, unlike some petroleum-based plastics.

- Recyclability: PET can be recycled but often ends up downcycled into lower-grade products. PLA needs specialized composting facilities to decompose properly, but it doesn’t produce toxic residues.

How to Dispose of PLA Products in Canada

Disposing of PLA properly is key to making sure it truly benefits the environment. While it’s made from plants, PLA doesn’t break down efficiently in landfills or home compost bins, since it needs specific conditions to decompose.

Here’s what you need to know about PLA disposal across Canada:

- Industrial Composting: PLA needs high heat (around 60°C) and controlled moisture to break down into water and carbon dioxide within 2–3 months. Only BPI-certified PLA products are accepted in these facilities.

- Landfill Disposal: PLA won’t compost in a landfill environment — instead, it can remain intact for decades due to the lack of oxygen and heat. It’s best to avoid this route whenever possible

- Recycling: PLA can’t go in your blue bin with PET plastics. While technically recyclable, most Canadian facilities don’t yet process bioplastics separately.

Regional acceptance:

Rules vary by province and even by city:

- British Columbia: Some programs like Recycle BC accept certified compostable packaging.

- Ontario: Most municipal programs don’t yet accept PLA in green bins, but private composters may.

- Quebec: Select programs accept PLA and other bioplastics through Plastic Pact Canada initiatives.

💡 Tip: Always check your local municipality’s waste sorting guide before disposal. You can find regional composting programs on Canada.ca’s municipal waste directory.

The Eco Guardian Difference

PLA packaging is changing the way we think about sustainability — durable, functional, and compostable without compromise. At Eco Guardian, we make it simple to choose better packaging that performs as well as it protects the planet.

When choosing compostable packaging, you need a partner whose standards are verifiable and whose supply is reliable. Here’s what sets us apart:

- Proven Performance: Every Eco Guardian product is designed for real-world use — strong, reliable, and safe.

- Certified Compostability: We ensure our PLA products meet strict environmental standards with certifications including BPI, ASTM D6400/D6868, and EN13432, so you can trust they’ll actually compost as intended.

- Canadian Accountability: Our team understands regional composting systems and regulations across Canada, helping you choose compliant packaging solutions that truly fit your sustainability goals.

Make the sustainable choice the easy choice. Explore your options now:

- For Homes, Events, & Small Orders: Shop our compostables here.

- For Wholesale & Foodservice: View our catalog or contact us for custom solutions